Rethinking gypsum & concrete wall & facade finishing

with our patent pending spray method and technology.

One nozzle, two worlds

Albér SprayTech has introduced a new, patent-pending spray gun designed to deliver reliable, high-quality application across both gypsum-based products and concrete slurries. Built around a precisely engineered mixing chamber and an extended outlet, the tool bridges two material categories that traditionally require separate equipment.

Conventional slurry and plaster spray guns typically use fixed nozzles, forcing material through small openings at high pressure. This often results in irregular spray patterns, material waste, uneven layers, and extra smoothing or cleanup. Albér SprayTech’s updated design avoids these issues by using an air-assisted internal mixing chamber, where

compressed air and liquid material combine immediately before leaving the gun. The elongated outlet then spreads the mixture as a smooth, controlled sheet—suitable for both fine gypsum applications and dense slurry mortars. The result is a cleaner workflow, fewer passes to achieve full coverage, and a more uniform coating thickness.

The Gun

Albér SprayTech spray gun is designed to deliver precise, consistent application across a wide range of materials. Its air-assisted internal mixing chamber combines compressed air and liquid compound just before release, while the elongated outlet forms a stable, uniform sheet of material.

This patent-pending design reduces waste, minimises overspray and ensures even coverage — making the tool a reliable choice for everything from standard gypsum plasters to high-density mortars and specialised fire-protection products.

Applications

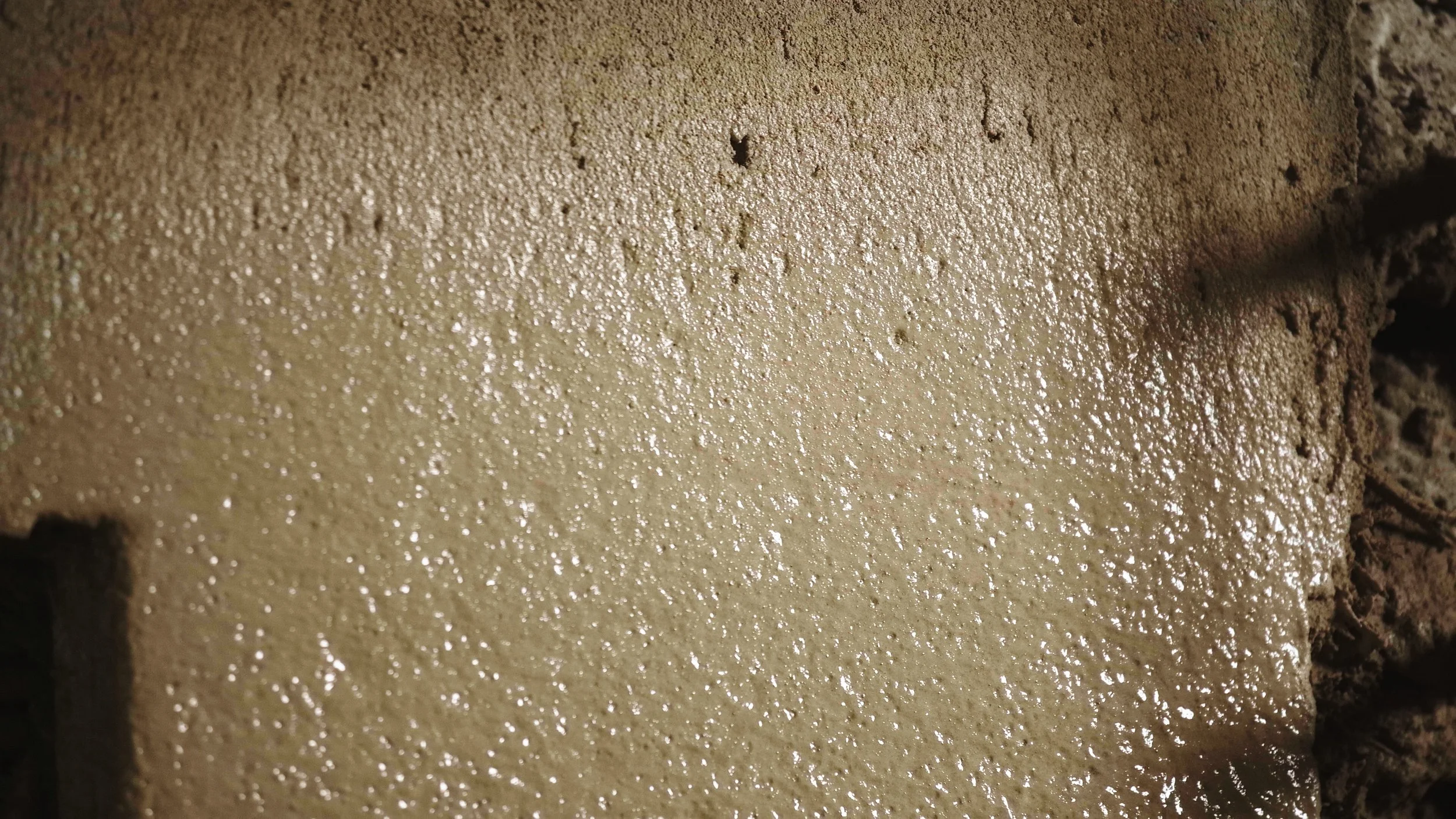

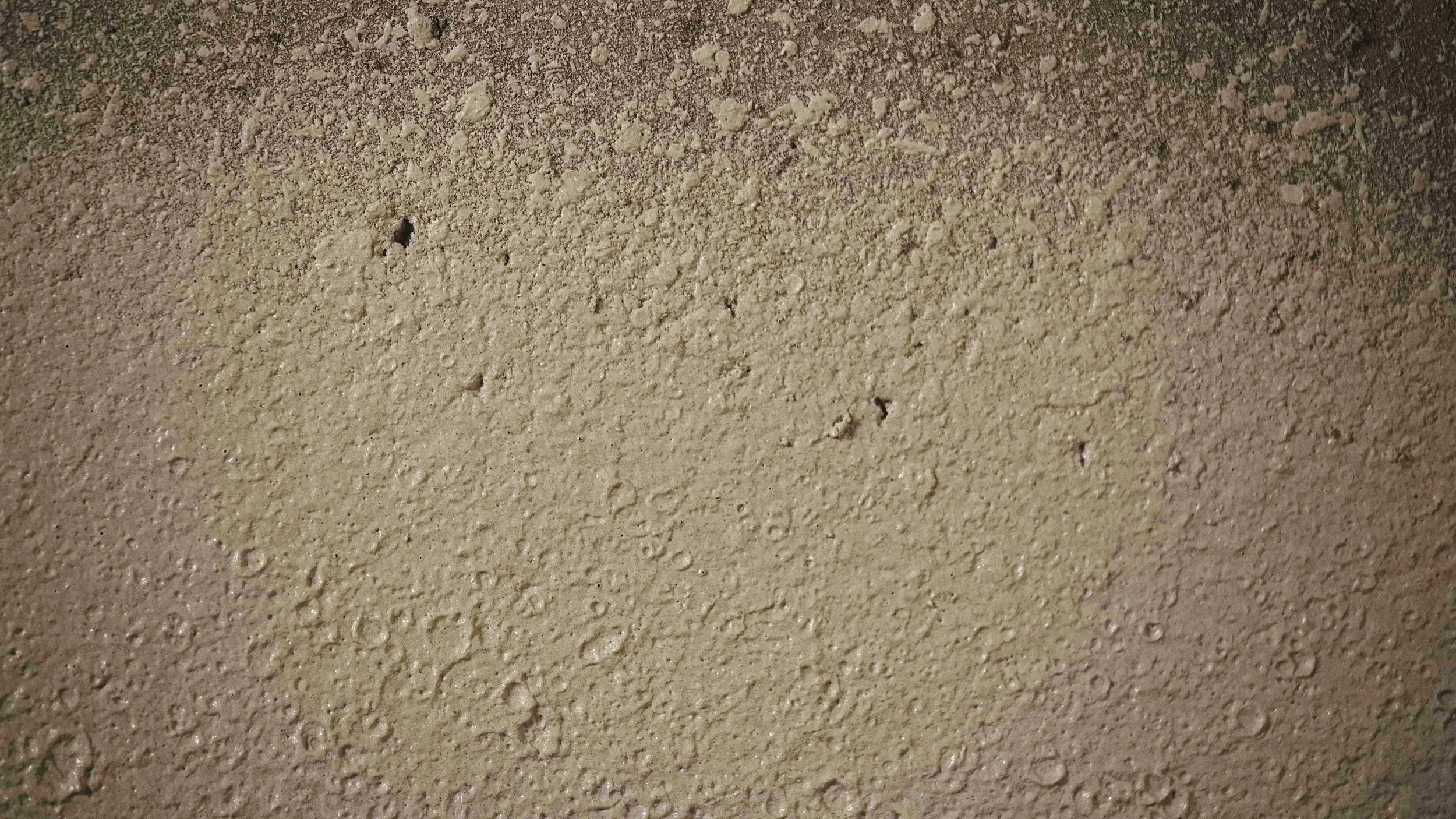

Clean and controlled slurry spraying In field trials at a major Danish construction firm, the gun was tested with concrete slurry coatings, operated with a standard compressor at just 4 bar. The even output and low overspray make it ideal for structural fireproofing overlays, repair coatings, decorative concrete finishes and retrofit projects. By enabling low-pressure operation with a wide, even spray, the gun simplifies fine concrete applications that previously required heavy or messy equipment.

Fire safety use

Albér SprayTech’s dual-use spray gun is also being developed for use with fire-protective materials such as fire cement and fire-resistant gypsum. Thanks to its air-assisted mixing chamber, the tool applies a smooth, uniform sheet of material — ensuring consistent layer thickness, which is essential for reliable fire safety performance.

The spraying method behind the system is patent-pending and is currently undergoing further development to optimise application quality, material efficiency and compatibility with high-performance fire-protection coatings.

Benefits

Speed & Efficiency

Finish walls and facades in half the time. Projects stay on schedule, and teams move faster from one phase to the next.

Cleaner Process

Less dust, less debris, and almost zero waste. Crews spend time building, not cleaning up.

Health & Safety

No more heavy lifting of gypsum boards. The spraygun is ergonomic, reducing strain and the risk of workplace injuries.

Durability/Quality

Surfaces are strong and seamless. The spray seals around pipes and outlets, improves fire safety, resists mold and flooding damage.

Sustainability

Traditional methods generate piles of off-cuts and waste. Our method uses only what is needed — no paper, no excess, fully recyclable.

Contact us

Interested in learning more and/or acquiring the Albér Spraytech spraygun? Don’t hesitate to get in touch. You are welcome to call, write or use the submission form below.

Kasper Albér

Phone: +45 91 92 19 10

Email: KA@alberspraytech.com